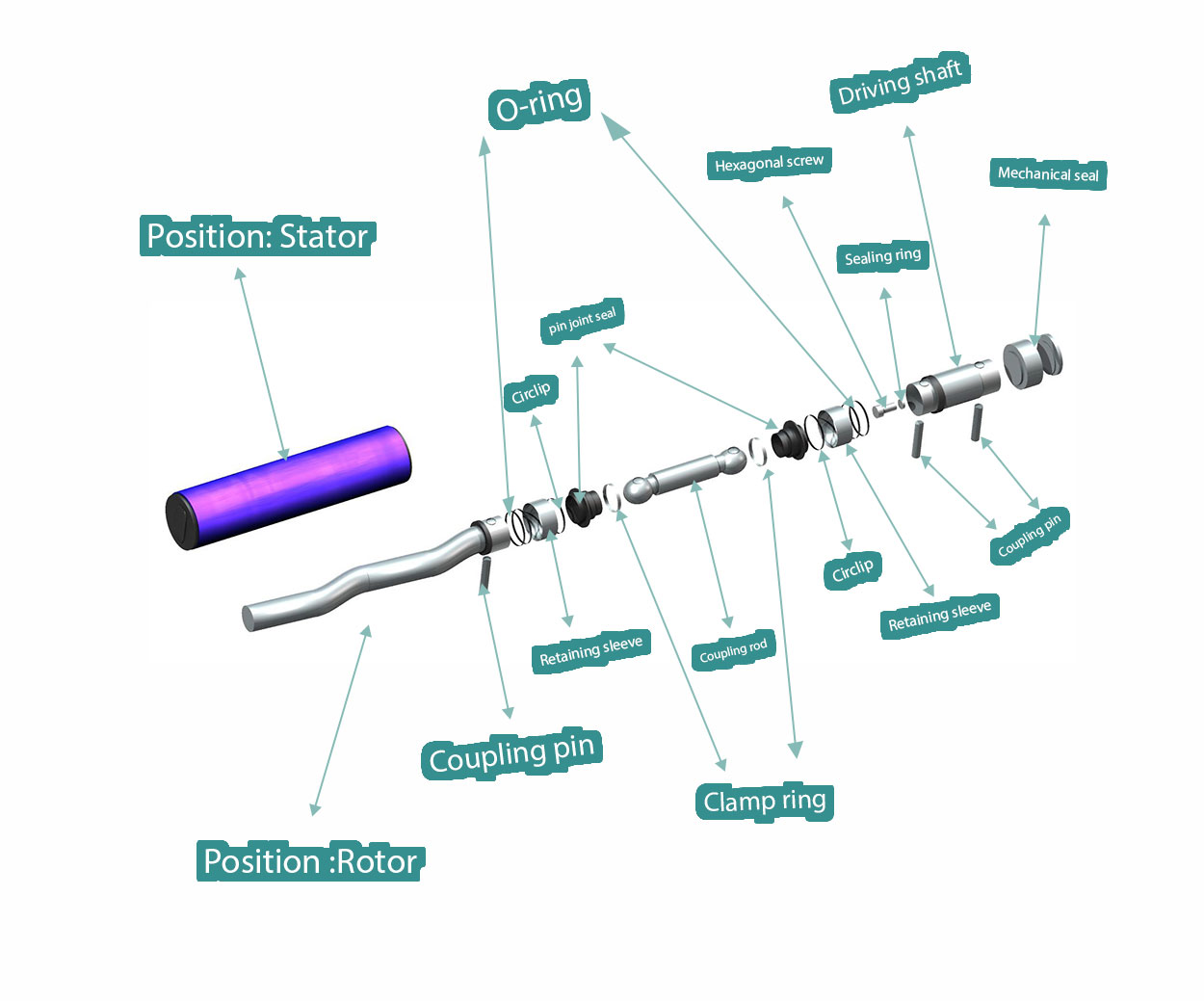

We can offer alternative progressive cavity pump parts for Netzsch® Brand NE and NM series. Including stator, rotor, coupling rod, universal joint assembly, drive shaft, mechanical seal, mechanical seal casing, packing, packing chamber, and pump body, almost all can be provided.

Once you’ve identified the spare parts you need, contact us for your free quotation:[email protected]

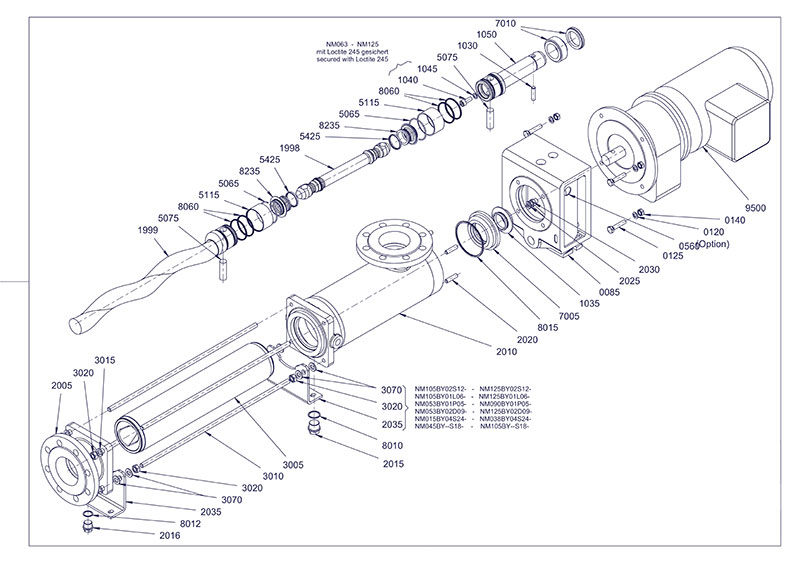

Exploded View of a Progressive Cavity Pump

Netzsch NM series spare parts list

| Pos No. | Description | Quantity |

| 5075 | pin | 2 |

| hexagon. Nut | 2 | |

| 0085 | drive stool | 1 |

| 0365 | elbow | 1 |

| 1020 | name plate | 1 |

| 1020 | number plate | 1 |

| 1030 | pin | 1 |

| 1035 | thrower | 1 |

| 1050 | connecting shaft | 1 |

| 1998 | coupling rod | 1 |

| 1999 | rotor | 1 |

| 2005 | end socket | 1 |

| 2010 | pump housing | 1 |

| 2015 | drain plug | 3 |

| 2016 | drain plug | 1 |

| 2020 | bolt | 4 |

| 2035 | support | 1 |

| 3005 | stator | 1 |

| 3010 | thru bolt | 4 |

| 3015 | spring washer | 8 |

| 3070 | washer | 4 |

| 5065 | circlip | 2 |

| 5115 | sleeve | 2 |

| 5425 | clamp ring | 2 |

| 7015 | stuffing box housing | 1 |

| 7030 | bolt | 2 |

| 7040 | packing | 6 |

| 8010 | gasket | 3 |

| 8012 | gasket | 1 |

| 8015 | O-ring | 1 |

| 8060 | O-ring | 4 |

| 8235 | SM-pin joint seal | 2 |

| 9510 | helical geared motors | 1 |

Aftermarket Netzsch Progressive Cavity Pump Parts

Applications

Progressive cavity pumps are used in many applications and all areas of industry.

From volumetric dosing to food applications, cosmetics to pharmaceutical, and of course, in the transfer of viscous fluids in all sectors, petrochemicals, environment, and many more…

Q: What are Netzsch pump parts?

A: Netzsch pump parts refer to the various components that make up a Netzsch pump, a type of positive displacement pump used in various industries. These parts can include stators, rotors, coupling rods, drive shafts, sealing systems, and other accessories.

Q: What materials are Netzsch pump parts made of?

A: Netzsch pump parts can be made of various materials, depending on the specific application and the type of pump. Some common materials include stainless steel, cast iron, rubber, and various types of plastics.

Q: How often should Netzsch pump parts be replaced?

A: The frequency of Netzsch pump part replacement depends on several factors, including the type of pump, the operating conditions, and the maintenance schedule. In general, it is recommended to replace worn or damaged parts as soon as possible to avoid further damage to the pump.

Q: Where can I buy Netzsch pump parts?

A: Netzsch pump parts can be purchased from a variety of suppliers, including authorized Netzsch distributors and aftermarket suppliers. It is important to ensure that any parts purchased are compatible with your specific pump model.

Q: How do I install Netzsch pump parts?

A: The installation process for Netzsch pump parts can vary depending on the specific component and the type of pump. It is important to follow the manufacturer’s instructions carefully and to ensure that all components are installed correctly to avoid damage or malfunction.

Q: What should I do if my Netzsch pump is not working properly?

A: If your Netzsch pump is not working properly, it is important to first check for any obvious signs of damage or wear on the pump and its components. If the problem persists, it may be necessary to consult a professional pump technician or contact Netzsch customer service for assistance.

Q: Can Netzsch pump parts be repaired?

A: In some cases, Netzsch pump parts can be repaired rather than replaced, depending on the type and extent of the damage. It is important to consult with a qualified pump technician or Netzsch customer service to determine the best course of action.

Commitment

We can offer a wide range of 100 % compatible Netzsch® spare parts of the highest quality standard at the best prices!

A progressive cavity pump rotor, also known as a screw pump rotor, is a critical component of a progressive cavity pump. It is responsible for moving fluids through the pump by rotating inside the stator, creating a cavity that moves the fluid from the suction to the discharge side of the pump. In this article, we will discuss the functions, materials, and replacement options for progressive cavity pump rotors.

Functions

The progressive cavity pump rotor plays a crucial role in the operation of the pump. The rotor’s helical shape works in tandem with the stator’s cavity to create a seal, trapping and moving fluid from the pump’s suction to the discharge side. The rotor’s design also enables it to handle fluids with varying viscosities, making it a versatile choice for a wide range of industries, including oil and gas, food and beverage, and wastewater treatment.

Materials

Progressive cavity pump rotors are typically made from a range of materials, including stainless steel, hardened steel, and elastomers. Stainless steel rotors are the most common choice for industrial applications, offering high durability and resistance to corrosion. Hardened steel rotors are used for high-pressure applications, while elastomer rotors are used for food and pharmaceutical processing, as they offer excellent chemical resistance and sanitary compliance.

Replacement Options

When it comes to replacement options for progressive cavity pump rotors, there are several brands and manufacturers to choose from. The two most common brands are Netzsch and Mono, with each offering their own unique line of rotor options.

Netzsch offers a range of progressive cavity pump rotors, including their Nemo® line of rotors, which feature a unique four-point connection system that offers superior strength and durability. The Nemo® line also includes rotors made from materials such as stainless steel, Hastelloy, and titanium, making them suitable for a variety of applications.

Mono also offers a range of progressive cavity pump rotors, including their EZstrip® line of rotors, which are designed for easy maintenance and replacement. The EZstrip® line features rotors that can be removed without the need for special tools, making them an ideal choice for applications where downtime must be minimized.

In addition to these brands, there are also several third-party manufacturers that offer compatible progressive cavity pump rotors that can be used as replacements for Netzsch or Mono rotors. These options can often provide a more cost-effective solution while still maintaining the quality and performance standards of the original equipment.

In conclusion, progressive cavity pump rotors are a crucial component of a progressive cavity pump, playing a critical role in moving fluids through the pump. By understanding the functions, materials, and replacement options for progressive cavity pump rotors, users can ensure efficient and reliable pump operation while minimizing downtime and maintenance costs.