Essential details

Voltage:220-440v

Structure: Single-stage Pump

Speed:2900r/min

Liquid: Acid Alkali Liquid

Model Number: CQ

Customized support: OEM, ODM

Feature

- CQ light stainless steel magnetic pump is a new type of industrial pump with a full seal, no leakage, no pollution, high efficiency, and energy saving;

- The pump body, impeller, diaphragm, pump shaft, inner rotor, isolation sleeve, and other overcurrent components are all made of high-quality stainless steel or special materials for precision casting;

- The magnet is made of ferrite magnet, which has good magnetic properties, high-temperature resistance, and no demagnetization;

- The moving ring and sliding bearing are made of graphite, PTFE, and other materials with high wear resistance and temperature resistance, which can effectively ensure the service life of the pump;

- The seal adopts a closed static seal, which completely solves the leakage of the medium;

- No need for independent lubrication and cooling water, reducing energy consumption;

- The direct-connected back-pull design does not need to disassemble the pipeline, and the maintenance is convenient;

- Horizontal installation, compact structure, small footprint, low vibration, low noise, and particularly stable operation;

- The external magnet is directly connected with the rotating shaft of the motor and adopts a direct-connected type, which has the advantages of simple structure, no need for centering, high transmission efficiency, low noise, and small vibration.

Application

Widely used in petroleum, chemical, alkali production, smelting, rare earth, pesticides, dyes, medicine, papermaking, electroplating, electrolysis, radio, chemical foil, scientific research institutions, national defense industry, and other production processes to transport corrosive liquids, especially suitable for flammable, Explosive, volatile, toxic, high temperature, strong alkali, organic solvent and the transportation of precious liquids.

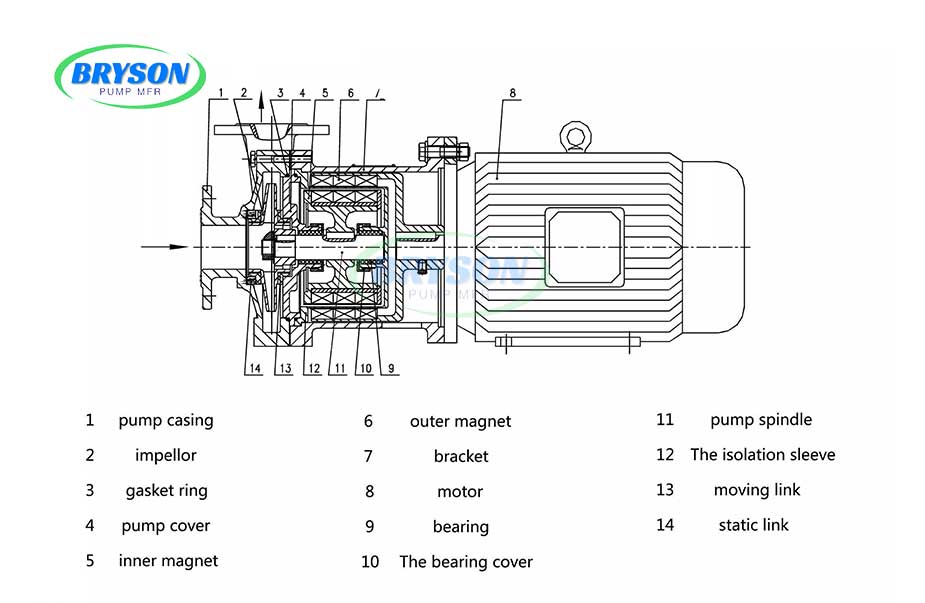

Structure diagram

Parameters Table

| model | Import (mm) | Export

(mm) |

flow

(m3/h) |

Go up(m) | Motor Power | Rotating speed(rpm) | Voltage(v) |

| 16CQ-8 | 16 | 12 | 1.8 | 8 | 0.18 | 2900 | 220/380 |

| 20CQ-12 | 20 | 12 | 3 | 12 | 0.37 | 2900 | 220/380 |

| 25CQ-15 | 25 | 20 | 5.4 | 15 | 1.1 | 2900 | 380 |

| 32CQ-15 | 32 | 25 | 6.6 | 15 | 1.1 | 2900 | 380 |

| 32CQ-25 | 32 | 25 | 4.8 | 25 | 1.1 | 2900 | 380 |

| 32CQ-32 | 32 | 32

32 |

3.2 | 32 | 1.5 | 2900 | 380 |

| 40CQ-20 | 40 | 10 | 20 | 2.2 | 2900 | 380 | |

| 40CQ-32 | 40 | 32 | 11.5 | 32 | 4 | 2900 | 380 |

| 50CQ-25 | 50 | 40 | 14.5 | 25 | 4 | 2900 | 380 |

| 50CQ-32 | 50 | 40 | 13 | 32

50 |

4

5.5 |

2900 | 380 |

| 50CQ-50 | 50 | 32 | 8 | 2900 | 380 | ||

| 65CQ-25 | 65 | 50 | 17

27 |

25 | 5.5 | 2900 | 380 |

| 65CQ-35 | 65 | 50 | 35 | 7.5 | 2900 | 380 |

FAQS:

1. Q: How to customize pumps and mechanical seals?

A: Customers could send us application data, we will select suitable pump and seal types, or clients could send us drawings, We are well in OEM and ODM.

2. Q: What information do I need to offer for a quotation?

A: Please provide the following information to our email [email protected] as much as possible

Medium: ____________

Caliber:____________

Specific Gravity: _______

Temperature: _________

Capacity/Flow: ________m3/h

Head: _________m

Voltage: ____________V

Frequency: _________Hz

Power:_____________KW

3. Q: What is your minimum quantity?

A: One set is also welcome to us.