Description

Versatile Applications

The G-Type Single Screw Pump is widely used in various industries due to its versatility. Some common applications include:

- Food and Beverage Industry: The pump is suitable for transferring viscous food products, such as chocolate, creams, sauces, and dairy items.

- Chemical and Petrochemical Industry: It can handle corrosive chemicals, adhesives, resins, and solvents effectively.

- Oil and Gas Industry: The pump is utilized for crude oil transfer, drilling mud circulation, and other applications requiring precise fluid control.

- Pharmaceutical Industry: It is suitable for transferring pharmaceutical ingredients, ointments, creams, and other viscous products.

Key Advantages of the G-Type Single Screw Pump

Using a G-Type Single Screw Pump offers several advantages, including:

- Gentle Product Handling: The pump’s design ensures minimal product degradation and shear, preserving the quality and integrity of the pumped substance.

- High Volumetric Efficiency: The pump’s positive displacement mechanism delivers consistent flow rates, even when handling varying viscosities or pressures.

- Self-Priming Capability: The pump can self-prime and handle air or gas entrainment, minimizing the need for additional priming equipment.

- Wide Operating Range: The G-Type Single Screw Pump can handle a broad range of viscosities, from low to high, making it suitable for a diverse range of fluids.

- Low Noise and Vibration: The pump operates quietly and with minimal vibration, providing a comfortable working environment.

Maintenance and Care

Proper maintenance and care are essential for the optimal performance and longevity of the G-Type Single Screw Pump. Regular inspection, lubrication, and cleaning are recommended to ensure smooth operation and prevent the build-up of debris or contaminants. It is also important to follow the manufacturer’s guidelines for routine maintenance and spare part replacement.

Where to Find G-Type Single Screw Pumps

G-Type Single Screw Pumps are available from various suppliers and manufacturers specializing in fluid handling equipment. It is advisable to consult with reputable suppliers who can provide guidance on selecting the right pump based on your specific requirements. Additionally, manufacturers often provide comprehensive technical support and after-sales services to ensure customer satisfaction.

Specification

| Flow rate | Up to 45 m³/h |

| Head | Up to 120 m |

| Speed | max 1450 rpm |

| Temperature | Max 120 ℃ |

| Casing pressure | Up to 1.2 MPa |

| Shaft seal | Mechanical seal/Gland packing seal |

| Material | Cast iron/Stainless steel |

Structure and datasheet

| 1. Outlet | 2. Tie Rod | 3. Stator | 4. Rotor |

| 5. Universal Joint | 6. Feed Axis | 7. Coupling Rod | 8. Grand |

| 9. Bearing | 10. Bearing Block | 11. Bearing | 12. Drive Shaft |

| 13. Bearing Cap | 14. Coupling | 15. Basement | 16. Motor |

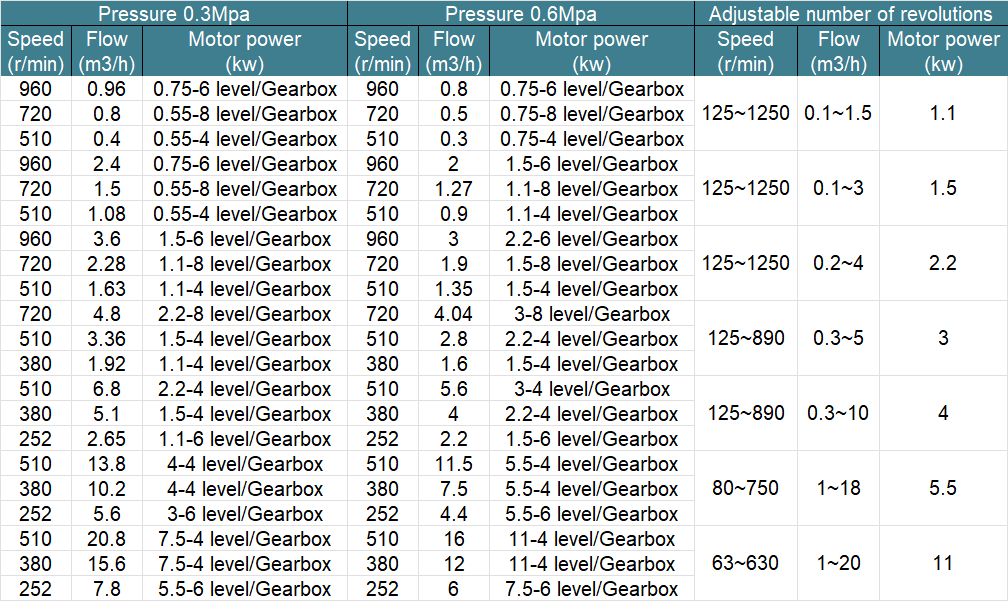

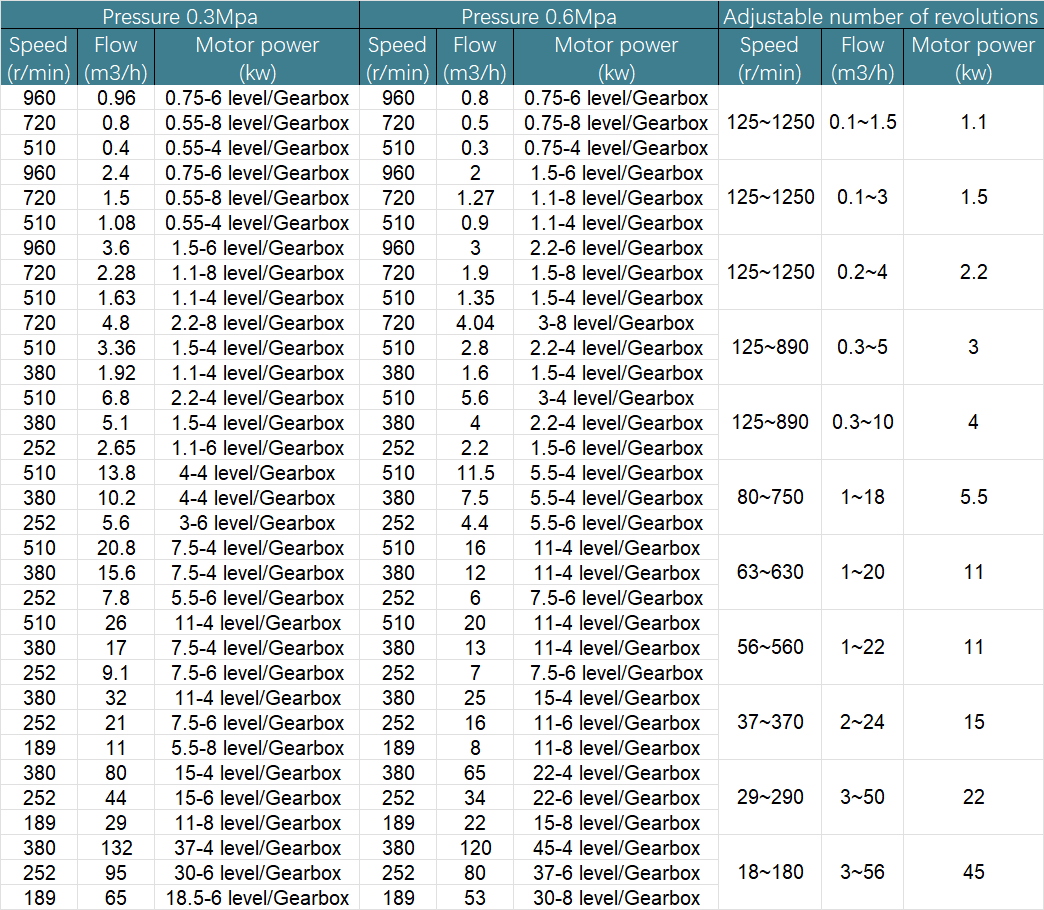

Single -level, performance parameters of gear transmission, electromagnetic speed regulating motor plus gear transmission or stepless transmission motor with gear gear:

Performance parameters are used for: G -type series, NW series, BN series, C -type series, etc. For specific selection, you can contact engineers

Single -level, performance parameters of gear transmission, electromagnetic speed regulating motor plus gear transmission or stepless transmission motor with gear gear:

The Pressure of the G-Type Single Screw Pump is Determined:

The maximum output pressure of the single G-Type Single Screw Pump is determined based on the number of guides of the jersey level, that is, the number of bands:

Level 1 G-Type Single Screw Pump: high work pressure is 0.6 mPa;

Level 2 G-Type Single Screw Pump: High work pressure is 1.2 MPA;

Level 4 single G-Type Single Screw Pump: high work pressure is 2.4 mPa;

Due to the different situations of the G-Type Single Screw Pump conveying medium, for the medium that contains severe wear, please refer to the number of band -grade levels.

Table 1: Choose the jujiao level according to the wear of the medium

| Wear first | Level | Two levels |

| No | 0.6MPa | 1.2MPa |

| Generally | 0.4MPa | 0.8MPa |

| Severe | 0.2MPa | 0.4MPa |

Table 2: Choose the Progressive Cavity Pump speed according to the abrasion of the medium

| Wear | Media Name | Rotating speed (rpm) |

| NO | Freshwater, coagulants, oil, slurry, meat foam, paint, soapy water, blood, glycerin | 200-400 |

| Generally | Mud, suspended solution, industrial wastewater, paint pigment, waste silk water (sugar), mash, fish, wheat bran, rapeseed oil sediment | 100-300 |

| Serious | Lumper slurry, clay, mud, pottery | 50-150 |

* When the specifications of the pump are large, the speed should be lower.

* The special cases that are delivered and their wear characteristics are given in the table. Please note that the characteristics of the medium change with the change of the concentration and temperature.

Table 3: Select the pump speed according to the medium viscosity

| Medium viscosity (cst) | 1-1000 | 1000-10000 | 10000-100000 | 100000-1000000 |

| Rotating speed (rpm) | 200-400 | 100-300 | <200 | <100 |

* You must also be based on experience when choosing a speed, because some other factors also affect the choice of speed. At the end, it is best to negotiate with the manufacturer while determining the above values.