Features of fluorine-lined magnetic drive pump series

1. The non-leakage fluorine-lined magnetic pump is a new type of industrial pump that is independently developed and designed with full sealing, no leakage, no pollution, and strong acid and alkali resistance.

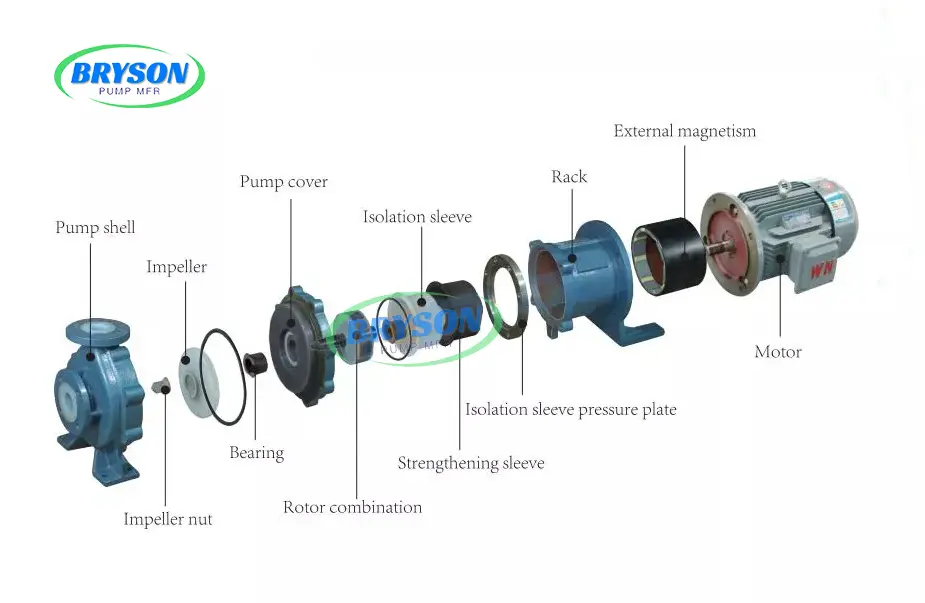

2. The pump body is made of cast iron lined with fluoroplastics (PTFE, FEP, PFA) by integral sintering and pressing. The inner rotor, pump cover impeller, isolation sleeve, and other over-current components are integrally sintered with metal inserts and outer fluoroplastics.

3. The magnet adopts a new type of permanent magnet, which has good magnetic properties, high-temperature resistance, and no demagnetization.

4. The shaft sleeve and sliding bearing are made of high wear-resistant silicon carbide, graphite, PTFE, and other materials.

5. It not only has the advantages of compact structure, beautiful appearance, small volume, low noise, and reliable operation of the ordinary magnetic pump but also can transport any concentration of acid, alkali, oxidant, and other fluorine corrosion properties without damage.

Other features

- High levels of durability and reliability

Manufactured to heavy-duty specifications for process use, these magnetic drive pumps can endure continuous operation for a long time under demanding conditions. The main structural materials of the pump are reinforced with metal to improve mechanical strength.

- Strong corrosion and heat resistance

These pumps are manufactured mainly from fluororesin and SiC. Three standard types of fluororesins are used: ETFE and PFA. Especially, the PFA type allows high-temperature liquids (up to 120˚C) to be handled. EL-grade chemicals can also be handled.

- Useful even in petrochemical plants

The casing cover of these pumps is constructed with FCD (ductile cast iron). Therefore, these pumps can be used in petrochemical plants where conventional resin-constructed pumps could not be used.

- Replacements for conventional sealed pumps.

Application

Products are widely used in petroleum, chemical, acid, alkali, smelting, rare earth, pesticides, dyes, medicine, papermaking, electroplating, pickling, radio, chemical foil, scientific research institutions, defense industry, and other industries to transport acid and alkali of any concentration It is suitable for the transportation of nature, oils, rare earth precious liquids, toxic liquids, volatile chemical media, especially flammable, leaky and explosive liquids.

Parameters Table

| Model | Flow | Head | Efficiency | NPSH | Import&Export | Speed | Motor Power |

| m³/h | m | % | m | mm | r/min | kw | |

| CF32-20-125 | 3.6 | 20 | 18 | 3 | 32*20 | 2900 | 1.1 |

| CF32-20-160 | 3.6 | 32 | 20 | 3 | 32*20 | 2900 | 2.2 |

| CF50-32-125 | 12.5 | 20 | 56 | 3.2 | 50*32 | 2900 | 1.5 |

| CF50-32-160 | 12.5 | 32 | 46 | 3.2 | 50*32 | 2900 | 4 |

| CF50-32-200 | 12.5 | 50 | 43 | 3.2 | 50*32 | 2900 | 5.5 |

| CF50-32-250 | 25 | 80 | 36 | 3.2 | 50*32 | 2900 | 11 |

| CF65-50-125 | 18 | 20 | 55 | 3.5 | 65*50 | 2900 | 3 |

| CF65-50-150 | 25 | 25 | 57 | 3.5 | 65*50 | 2900 | 4 |

| CF65-50-160 | 25 | 32 | 52 | 3.5 | 65*50 | 2900 | 5.5 |

| CF65-40-200 | 25 | 50 | 46 | 3.5 | 80*40 | 2900 | 11 |

| CF65-40-250 | 25 | 80 | 47 | 3.5 | 80*40 | 2900 | 15 |

| CF80-65-125 | 50 | 20 | 45 | 4.5 | 80*65 | 2900 | 7.5 |

| CF80-65-160 | 50 | 32 | 48 | 4.5 | 80*65 | 2900 | 11 |

| CF80-50-200 | 50 | 50 | 56 | 4.5 | 80*50 | 2900 | 15 |

| CF80-50-250 | 50 | 80 | 53 | 4.5 | 80*50 | 2900 | 30 |

| CF100-80-125 | 100 | 20 | 54 | 5 | 100*80 | 2900 | 15 |

| CF100-80-160 | 100 | 32 | 56 | 5 | 100*80 | 2900 | 18.5 |

FAQS:

1. Q: How to customize pumps and mechanical seals?

A: Customers could send us application data, we will select a suitable pump and seal types, or clients could send us drawings, We are well in OEM and ODM.

2. Q: What information do I need to offer for a quotation?

A: Please provide the following information to our email [email protected] as much as possible

Medium: ____________

Caliber:____________

Specific Gravity: _______

Temperature: _________

Capacity/Flow: ________m3/h

Head: _________m

Voltage: ____________V

Frequency: _________Hz

Power:_____________KW

3. Q: What is your minimum quantity?

A: One set is also welcome to us.