The feeding Progressing Cavity Pump is an internally meshing closed screw pump, a rotary positive displacement pump. This pump has strong adaptability to the medium, stable flow, slight pressure pulsation, good suction performance, and can transport various fluids. In addition to the media, it can also transport highly viscous media, media containing hard suspended particles or solid particles, and media containing fibers, with suitable adjustment performance, wide range, and high efficiency.

Overview

Flow: 20m3/h

Lift: 30M

Pressure: 0.3Mpa

Speed: 280

Efficiency: 70%

Suction diameter: 100mm

Excluded caliber: 100mm

Power: 5.5Kw

Product application range

Feeding Progressing Cavity Pumps are used in food, chemical industry, petroleum, power plant, papermaking, metallurgy, mining industry, sewage, river pond dredging, etc., supporting filter press, high-lift conveying materials (honey, bean paste, mud, mortar, chemical Liquid, liquid medicine)

Characteristics of the Feeding Progressing Cavity Pump

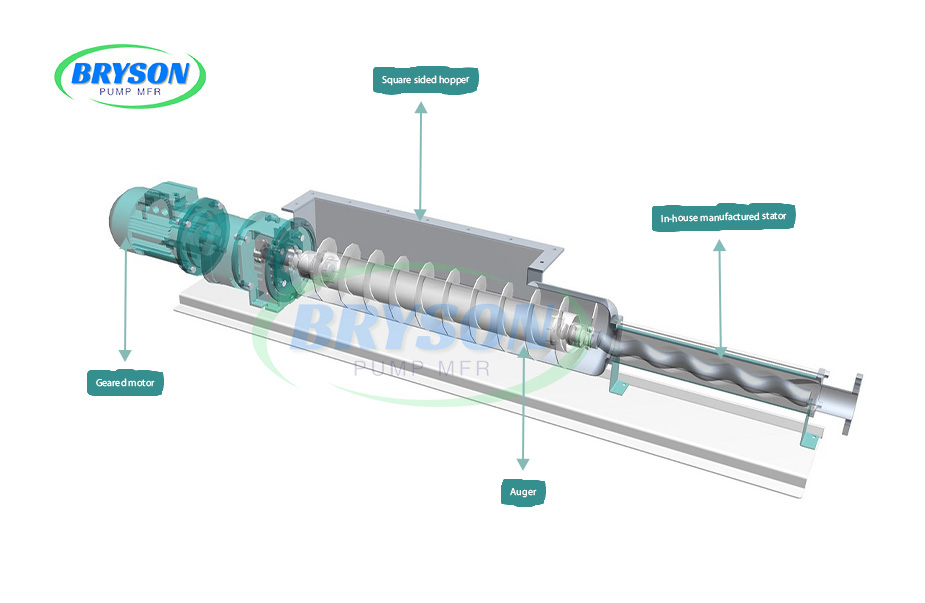

- Hopper cavity with rectangular inlet flange and spiral feeder and squeeze cavity, To facilitate the flow of slow and paste medium into the rotor and stator between the hole.

- Continuous low pulsation transmission, not affected by pressure and viscosity fluctuation

- The conveying capacity is proportional to the rotational speed and can achieve high precision measurement in the whole speed range.

- High pressure no valve transmission

- The stator with a hopper-type feed mouth can make the medium easy to enter the conveying cavity.

- Low noise, slight vibration

- Wide range of flow and pressure