Essential details

Voltage:220-400V

Structure: Single-stage Pump

Product name: High temperature resistant stainless steel magnetic pump

Model Number: CB

Customized support: OEM, ODM

Feature

- The CB Explosion-proof stainless steel magnetic drive chemical hydrochloric acid pump is a new type of industrial pump that is independently developed and designed by the company with a full seal, no leakage, no pollution, and corrosion resistance.

- The magnet adopts a new type of permanent magnet, which has good magnetic properties, high-temperature resistance, and no demagnetization.

- The shaft sleeve and sliding bearing are made of silicon carbide, tetrafluoro-graphite, alloy material, and the unique bearing seat assembly and thrust ring design of Hongyun Pump Industry make the pump run more stably and have better wear resistance. The whole machine has a longer service life and higher efficiency.

Application

It is widely used in petroleum, chemical, pharmaceutical, metallurgy, electroplating, environmental protection, food, scientific research institutions, the national defense industry, and other production processes to transport flammable, explosive, volatile, toxic, and precious liquids. It is suitable for conveying liquids that do not contain hard particles and fibers with a suction pressure not greater than 0.2MPa to a maximum working pressure of 1.6MPa, a temperature not greater than 1600kg/m3, and a viscosity not greater than 30x 10-6m2/S.

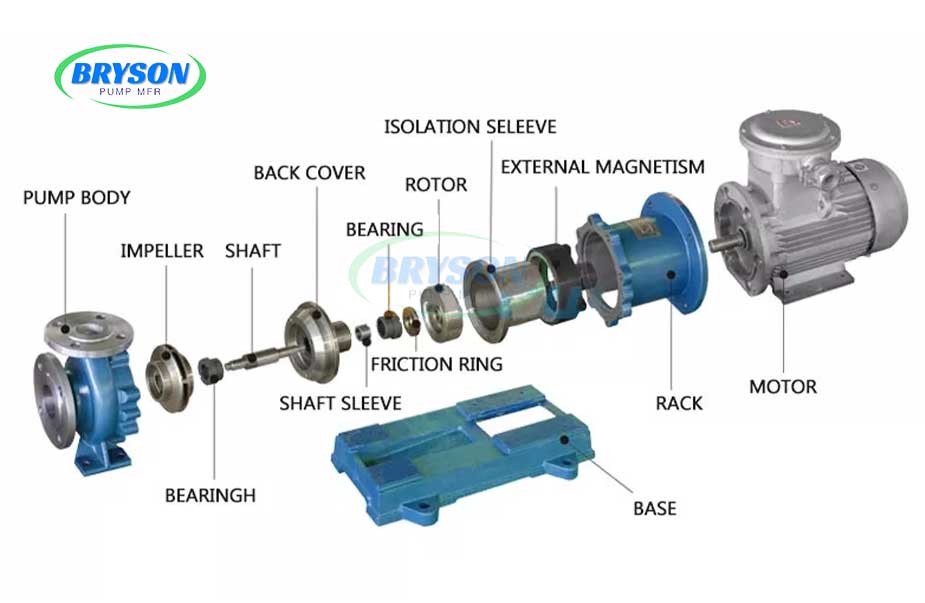

Structure diagram

Parameters Table

| model | caliber(mm) | flow(m3/h) | Go up(m) | Motor Power(kw) | Voltage(v) | |

| import | Export | |||||

| CB32-20-125 | 32 | 20 | 3.2 | 20 | 1.1 | 380 |

| CB32-20-160 | 32 | 20 | 3.2 | 32 | 1.5 | 380 |

| CB40-25-125 | 40 | 25 | 6.3 | 20 | 2.2 | 380 |

| CB40-25-160 | 40 | 25 | 6.3 | 32 | 3 | 380 |

| CB40-25-200 | 40 | 25 | 6.3 | 50 | 5.5 | 380 |

| CB50-32-125 | 50 | 32 | 12.5 | 20 | 3 | 380 |

| CB50-32-160 | 50 | 32 | 12.5 | 32 | 4 | 380 |

| CB50-32-200 | 50 | 32 | 12.5 | 50 | 7.5 | 380 |

| CB50-32-250 | 50 | 32 | 12.5 | 80 | 18.5 | 380 |

| CB65-50-125 | 65 | 50 | 25 | 20 | 4 | 380 |

| CB65-50-160 | 65 | 50 | 25 | 32 | 7.5 | 380 |

| CB65-40-200 | 65 | 40 | 25 | 50 | 15 | 380 |

| CB65-40-250 | 65 | 40 | 25 | 80 | 18.5 | 380 |

| CB80-65-125 | 80 | 65 | 50 | 20 | 7.5 | 380 |

| CB80-65-160 | 80 | 65 | 50 | 32 | 15 | 380 |

| CB80-50-200 | 80 | 50 | 50 | 50 | 18.5 | 380 |

| CB80-50-250 | 80 | 50 | 50 | 80 | 37 | 380 |

| CB100-80-125 | 100 | 80 | 100 | 20 | 15 | 380 |

| CB100-80-160 | 100 | 80 | 100 | 32 | 18.5 | 380 |

| CB100-65-200 | 100 | 65 | 100 | 50 | 37 | 380 |

| CB100-65-250 | 100 | 65 | 100 | 80 | 55 | 380 |

FAQS:

1. Q: How to customize pumps and mechanical seals?

A: Customers could send us application data, we will select suitable pump and seal types, or clients could send us drawings, We are well in OEM and ODM.

2. Q: What information do I need to offer for a quotation?

A: Please provide the following information to our email [email protected] as much as possible

Medium: ____________

Caliber:____________

Specific Gravity: _______

Temperature: _________

Capacity/Flow: ________m3/h

Head: _________m

Voltage: ____________V

Frequency: _________Hz

Power:_____________KW

3. Q: What is your minimum quantity?

A: One set is also welcome to us.