Description

Eccentric screw pumps, also known as progressive cavity pumps or helical rotor pumps, are versatile and efficient devices used in various industrial applications. The unique design and operating principle of eccentric screw pumps make them suitable for a wide range of fluid handling tasks. This article explores the diverse application areas where eccentric screw pumps excel.

- Chemical Industry: Eccentric screw pumps are widely employed in the chemical industry due to their ability to handle corrosive and abrasive fluids. They can effectively pump chemicals, solvents, acids, and other aggressive substances, making them crucial for chemical processing plants, refineries, and chemical transfer operations.

- Food and Beverage Industry: In the food and beverage industry, eccentric screw pumps are utilized for gentle and hygienic product handling. These pumps can handle viscous fluids, such as chocolate, syrup, cream, and sauces, without damaging or altering their consistency. Additionally, eccentric screw pumps are suitable for handling delicate food products, such as fruits, vegetables, and even live fish, ensuring minimal product degradation.

- Wastewater Treatment: Eccentric screw pumps play a vital role in wastewater treatment facilities. They are capable of efficiently pumping various types of wastewater, including sewage, sludge, and industrial effluents. The non-clogging nature of eccentric screw pumps allows for the smooth handling of solids, making them ideal for applications involving high solids content and challenging wastewater conditions.

- Oil and Gas Industry: Eccentric screw pumps find extensive use in the oil and gas industry for pumping crude oil, drilling mud, and various types of hydrocarbons. These pumps offer reliable performance and can handle fluids with high viscosities and solid content commonly found in oilfield operations. The self-priming capability of eccentric screw pumps is advantageous for oil and gas applications, enabling efficient fluid transfer in challenging environments.

- Mining and Mineral Processing: In mining and mineral processing operations, eccentric screw pumps are employed for dewatering, slurry transfer, and tailings management. These pumps can handle abrasive slurries and effectively pump high-density solids. The robust construction of eccentric screw pumps ensures reliable operation in harsh mining conditions, making them indispensable for extracting and processing valuable minerals.

- Pharmaceutical and Cosmetics Industry: Eccentric screw pumps are widely used in pharmaceutical and cosmetics manufacturing due to their ability to handle shear-sensitive and high-value products. These pumps offer precise and controlled flow rates, ensuring gentle product handling without compromising product integrity. From pharmaceutical suspensions to cosmetic creams, eccentric screw pumps provide consistent performance in these critical industries.

Conclusion: Eccentric screw pumps have a broad application range, thanks to their versatility, reliability, and ability to handle challenging fluids. From chemical processing to food production, wastewater treatment to oil and gas operations, and mining to pharmaceutical manufacturing, eccentric screw pumps provide efficient and consistent fluid handling solutions across various industries. Their unique design and performance characteristics make them indispensable tools for numerous fluid handling challenges, contributing to the smooth operation of diverse industrial processes.

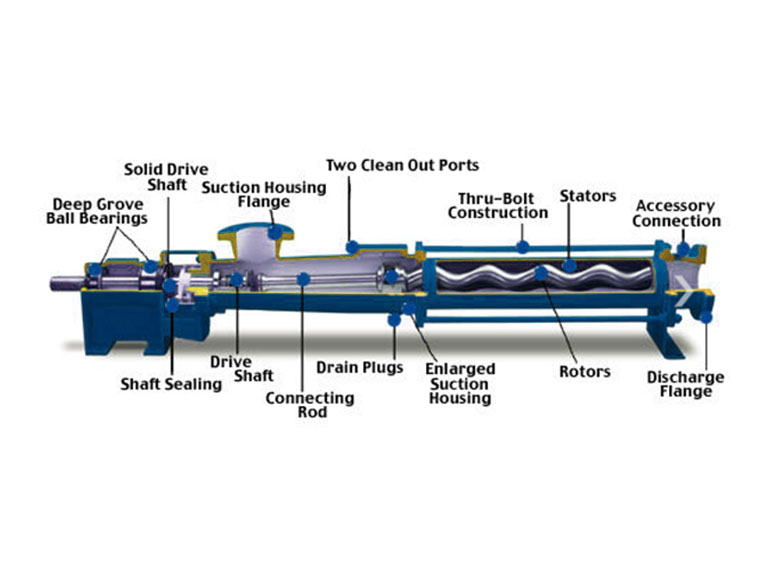

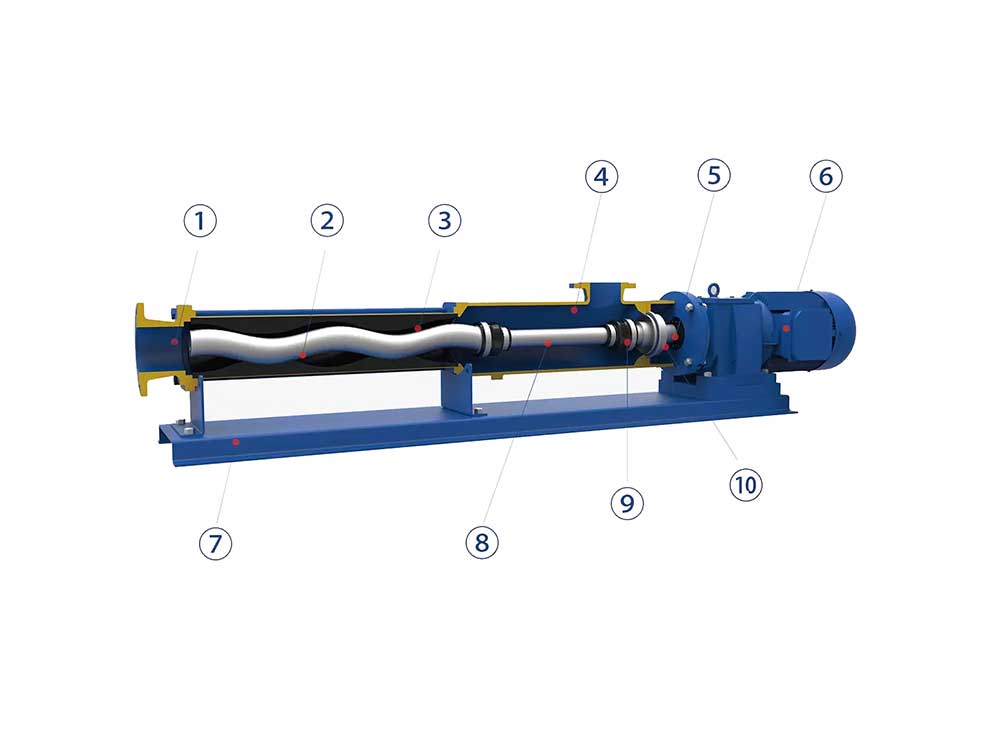

Eccentric Screw Pump Structure Diagram

| No. | Name | Material |

| 1 | Material-out chamber | HT200, 1Cr18Ni9Ti, 304, 316L, 2205, Ti |

| 2 | Rotor | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 3 | Stator | NR, NBR, Q, EPM, FKM |

| 4 | Suction chamber | HT200, 304, 316L, 2205, Ti |

| 5 | Driving shaft | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 6 | Gear motor | / |

| 7 | Base plate | 45#, 2Cr13, 304, 316L, 2205, Ti |

| 8 | Coupling rod | 45#, 2Cr13, 304, 316L, 2205, Ti (Heat-treatable and electroplated Cr) |

| 9 | Universal joint assembly | NBR + 45#, 2Cr13, 304, 316L |

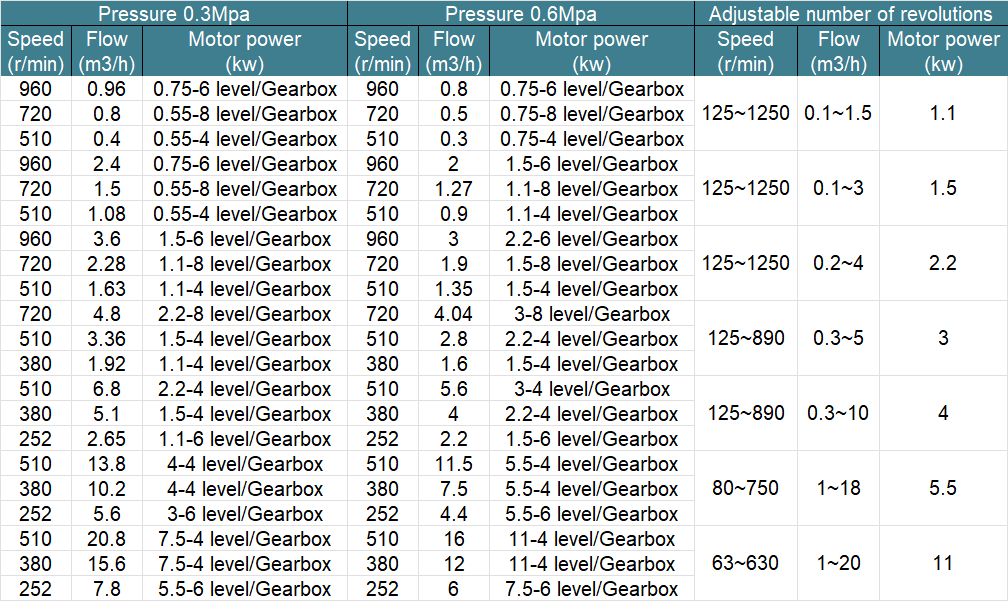

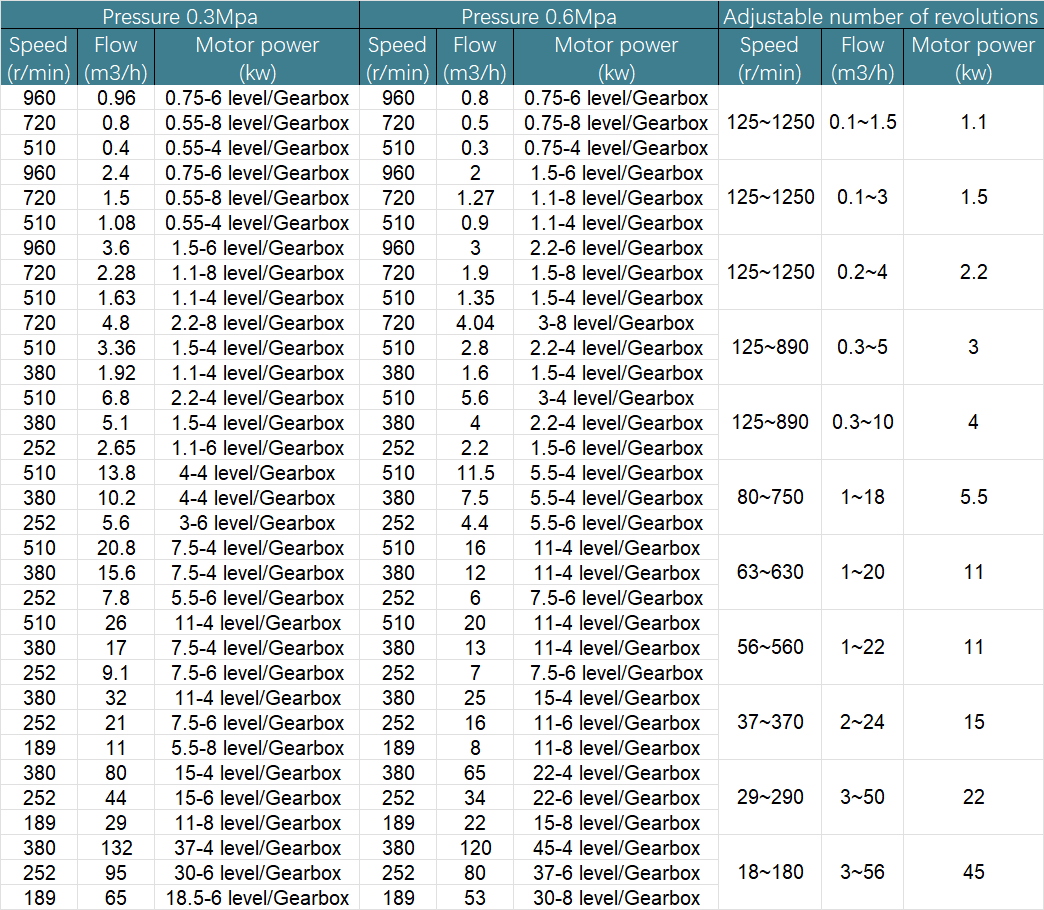

Single -level, performance parameters of gear transmission, electromagnetic speed regulating motor plus gear transmission or stepless transmission motor with gear gear:

Performance parameters are used for: G -type series, NW series, BN series, C -type series, etc. For specific selection, you can contact engineers

Single -level, performance parameters of gear transmission, electromagnetic speed regulating motor plus gear transmission or stepless transmission motor with gear gear:

The Pressure of the Eccentric Screw Pump is Determined:

The maximum output pressure of the single Progressive Cavity Pump is determined based on the number of guides of the jersey level, that is, the number of bands:

Level 1 Progressive Cavity Pump: high work pressure is 0.6 mPa;

Level 2 Progressive Cavity Pump: High work pressure is 1.2 MPA;

Level 4 single Progressive Cavity Pump: high work pressure is 2.4 mPa;

Due to the different situations of the Progressive Cavity Pump conveying medium, for the medium that contains severe wear, please refer to the number of band -grade levels.

Table 1: Choose the jujiao level according to the wear of the medium

| Wear first | Level | Two levels |

| No | 0.6MPa | 1.2MPa |

| Generally | 0.4MPa | 0.8MPa |

| Severe | 0.2MPa | 0.4MPa |

Single Progressive Cavity Pump Speed Selection

Due to its structural characteristics, the single Progressive Cavity Pump is mostly used in the liquid that transports higher viscosity and liquid containing particles. Therefore, the choice of the transfer is very critical. According to experience, list Table 2 and Table III. You can consider it comprehensively according to the specific situation.

Table 2: Choose the Progressive Cavity Pump speed according to the abrasion of the medium

| Wear | Media Name | Rotating speed (rpm) |

| NO | Freshwater, coagulants, oil, slurry, meat foam, paint, soapy water, blood, glycerin | 200-400 |

| Generally | Mud, suspended solution, industrial wastewater, paint pigment, waste silk water (sugar), mash, fish, wheat bran, rapeseed oil sediment | 100-300 |

| Serious | Lumper slurry, clay, mud, pottery | 50-150 |

* When the specifications of the pump are large, the speed should be lower.

* The special cases that are delivered and their wear characteristics are given in the table. Please note that the characteristics of the medium change with the change of the concentration and temperature.

Table 3: Select the pump speed according to the medium viscosity

| Medium viscosity (cst) | 1-1000 | 1000-10000 | 10000-100000 | 100000-1000000 |

| Rotating speed (rpm) | 200-400 | 100-300 | <200 | <100 |

* You must also be based on experience when choosing a speed, because some other factors also affect the choice of speed. At the end, it is best to negotiate with the manufacturer while determining the above values.

Eccentric Screw Pump Lining Rubber Material Selection

The single Progressive Cavity Pump lining is a rubber product, and it is also a destructive part of the single Progressive Cavity Pump. Its choices are good or bad, which directly affects the life of the band. Generally, the life of the band is 3-6 months. , Band may fall off from the steel pipe or drop the block. Therefore, we are required to understand the basic characteristics of rubber and the adaptability of a variety of different medias, and list Table IV and Table 5 according to our experience.

Table 4: Basic characteristics of rubber

| Rubber characteristics | NBR | CR | PPM | EPDM |

| Maximum temperature | +90°C | +80°C | +120°C | +100°C |

| Abrasion resistance | excellent | very good | excellent | very good |

| Aging | very good | very good | excellent | excellent |

| Oxygen | not work | excellent | excellent | excellent |

| Steam | very good | not work | excellent | excellent |

| Combustion | very good | excellent | excellent | excellent |

Table 5: Commonly used rubber for bushings of single screw pumps

| Rubber | EPDM | PPM | CR | NBR |

| Water | very good | very good | very good | very good |

| Vegetable oil | generally | very good | generally | very good |

| mineral oil | not work | very good | generally | very good |

| ammonia | generally | not work | not work | very good |

| Aromatic solvent | not work | very good | not work | not work |

| Thick alkali | very good | not work | very good | very good |

| Concentrated nitric acid | not work | generally | not work | not work |

| glacial acetic acid | not work | very good | not work | very good |

| Dilute sulfuric acid | very good | very good | not work | very good |

| Concentrated sulfuric acid | generally | very good | not work | not work |

| Dilute hydrochloric acid | very good | very good | very good | very good |

| Concentrated hydrochloric acid | very good | very good | not work | very good |

| Hot water | very good | not work | not work | generally |

| gasoline | not work | very good | generally | very good |

| Toluene | not work | very good | not work | not work |

| Toluene | not work | very good | not work | not work |

| Ethanol | very good | very good | very good | generally |

| kerosene | not work | very good | very good | very good |

| diesel fuel | not work | very good | not work | very good |

| Chloride hydrocarbon | not work | generally | not work | not work |

| Ketone -containing material | very good | not work | not work | not work |

| Alcohol -containing material | very good | very good | very good | very good |

| Lipid | very good | not work | not work | not work |

| Ether -containing material | very good | not work | not work | not work |

| Mud | very good | generally | generally | very good |

| Phosphate | very good | generally | very good | generally |

| Sodium carbonate | very good | not work | very good | very good |

| Gloss | very good | generally | generally | generally |

| Benzene 100 | not work | very good | not work | not work |

| Acetone | very good | not work | not work | not work |

| Linseed oil | very good | very good | very good | very good |

| Carbonide | not work | very good | not work | not work |

Frequently Asked Questions about the Eccentric Screw Pump

Q1: What is an Eccentric Screw Pump?

A1: An Eccentric Screw Pump, also known as a Progressive Cavity Pump or a Helical Rotor Pump, is a type of positive displacement pump. It is designed to handle a wide range of viscous fluids and is characterized by its unique pumping mechanism.

Q2: How does an Eccentric Screw Pump work?

A2: The pump consists of a single helical rotor, also known as a screw, and a stationary elastomeric stator. As the rotor rotates eccentrically within the stator, cavities are formed between the screw flights and the stator. These cavities progress from the suction side to the discharge side of the pump, pushing the fluid along.

Q3: What are the advantages of using an Eccentric Screw Pump?

A3: Eccentric Screw Pumps offer several advantages, including:

- Ability to handle highly viscous and abrasive fluids

- Self-priming capabilities

- Constant and smooth flow without pulsations

- High suction lift and pressure capabilities

- Gentle handling of shear-sensitive fluids

- Versatility in handling various fluid viscosities and solids content

Q4: In what applications are Eccentric Screw Pumps commonly used?

A4: Eccentric Screw Pumps find applications in a wide range of industries, including:

- Food and beverage: Handling of syrups, creams, sauces, and chocolate

- Oil and gas: Pumping of crude oil, drilling mud, and viscous additives

- Chemical processing: Transfer of adhesives, resins, polymers, and slurries

- Wastewater treatment: Pumping of sludge, slurry, and thickened fluids

- Pharmaceutical and cosmetics: Handling of creams, ointments, and lotions

Q5: Are Eccentric Screw Pumps suitable for sanitary applications?

A5: Yes, Eccentric Screw Pumps can be designed and manufactured to meet sanitary requirements. These pumps are available with features such as clean-in-place (CIP) and sterilize-in-place (SIP) capabilities, hygienic seals, and polished surfaces, making them suitable for use in the food, beverage, and pharmaceutical industries.

Q6: How should I select the right Eccentric Screw Pump for my application?

A6: When selecting an Eccentric Screw Pump, consider the following factors:

- Fluid viscosity and characteristics

- Flow rate and pressure requirements

- Solids content, if any

- Temperature and chemical compatibility

- System constraints and installation considerations

Consulting with a pump manufacturer or supplier can help in determining the most suitable pump for your specific application.

Q7: What maintenance is required for Eccentric Screw Pumps?

A7: Eccentric Screw Pumps generally require minimal maintenance. Regular inspection of the stator and rotor for wear, monitoring of seals and bearings, and lubrication of the drive system are recommended. It’s also important to follow the manufacturer’s guidelines for maintenance intervals and procedures.