To ensure the plastic magnetic drive pump operation process’s high efficiency and effectively reduce the failure rate during operation, the user should maintain it regularly. The cleaning of its spare parts is a vital link. How should plastic magnetic drive pump parts be adequately maintained?

In the cleaning of plastic magnetic drive pump parts, the cleaning standard of the plated cover and bonded positions is very high. Poor cleaning quality is often the cause of the failure of the coating or bonding, and the cleaning quality of the parts assembly dramatically impacts the service life of mechanical equipment. Significant, because the cleaning is seriously not up to standard, a large number of abrasives seep into important friction pairs or the lubricating oil passage is blocked by sundries, which leads to premature wear and accidental damage of mechanical equipment, which often occurs in some unprofessional repair work, must pay attention.

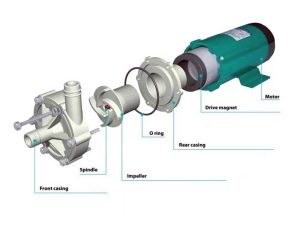

- Scrape off the scale and rust accumulated on the inner and outer surfaces of the impeller, seal rings, and bearings, and then clean and blow it off with water or compressed air.

- Clean the grease and rust accumulated on the connecting surface of the plastic magnetic drive pump housing.

- Clean the water seal pipe and check whether the pipeline is smooth.

After a period of application, users should also pay close attention to the operating status of the plastic magnetic drive pump and carry out corresponding maintenance work, which mainly includes:

- Check whether there are cracks or small holes on the impeller and whether the fixing nut of the impeller is loose. If there is any damage, it should be repaired or replaced. Check the gap at the impeller wear-reducing ring; if it exceeds the specified value, it should be repaired or replaced.

- Check the ball bearings. If the inner and outer shells are worn or moved, balls are worn, or there are black spots on the surface, they must be replaced. If it is still applicable, clean the bearing with gasoline or kerosene and store it with butter.

- When the transmission belt is not in use, the belt should be removed, washed, and dried with warm water and then stored in an area without direct sunlight, and do not store in a room with oil, corrosion, and smoke. Do not let the tape be stained with oily substances such as engine oil, diesel, or gasoline, and do not apply rosin and other sticky substances to the video. Before the tape is used, the white powder on the contact surface must be cleaned.

- If it is easy to disassemble and assemble, the plastic magnetic pump and pipeline can be removed and cleaned, and all the screws and bolts can be cleaned with a steel wire brush and then coated with engine oil or immersed in diesel oil for storage.