Description

Features

- Hygienic Design

Food-grade screw pump is made from high-quality materials that are safe for contact with food products. The pump has a hygienic design that ensures that there is no contamination of the food products during the pumping process.

- Easy to Clean

Food-grade screw pump is easy to clean, which makes it ideal for the food processing and manufacturing industry. The pump can be disassembled easily, and the parts can be cleaned separately. This feature ensures that there are no dirt, debris, or bacteria left in the pump after the cleaning process.

- High Efficiency

Food-grade screw pump has a high efficiency that allows them to pump food products at a fast rate. The pump can handle viscous products with ease, which makes it ideal for moving food products such as sauces, syrups, and creams.

- Adjustable Flow Rate

Food-grade screw pump has an adjustable flow rate that allows the user to control the speed of the pump. This feature is essential in the food processing and manufacturing industry, where different products require different flow rates.

Functions

- Transfer of Food Products

A food-grade screw pump is primarily used to transfer food products from one point to another. The pump is used to move food products from the production line to the packaging line, ensuring that the products are delivered efficiently and hygienically.

- Mixing and Blending

Food-grade screw pump is also used in mixing and blending applications. The pump can be used to mix different food products to create a uniform mixture. This feature is especially useful in the production of sauces, dressings, and desserts.

- Filling and Dispensing

Food-grade screw pump can be used to fill and dispense food products into containers. The pump can be used to fill bottles, jars, and other containers with accuracy and precision. This feature saves time and ensures that the products are filled to the correct level.

The Pressure of the Food-grade screw pump is Determined:

The maximum output pressure of the Food-grade screw pump is determined based on the number of guides of the jersey level, that is, the number of bands:

Level 1 Food-grade screw pump: high work pressure is 0.6 mPa;

Level 2 Food-grade screw pump: High work pressure is 1.2 MPA;

Level 4 Food-grade screw pump: high work pressure is 2.4 mPa;

Due to the different situations of the Food-grade screw pump conveying medium, for the medium that contains severe wear, please refer to the number of band -grade levels.

Table 1: Choose the jujiao level according to the wear of the medium

| Wear first | Level | Two levels |

| No | 0.6MPa | 1.2MPa |

| Generally | 0.4MPa | 0.8MPa |

| Severe | 0.2MPa | 0.4MPa |

Table 2: Choose the Food-grade screw pump speed according to the abrasion of the medium

| Wear | Media Name | Rotating speed (rpm) |

| NO | Freshwater, coagulants, oil, slurry, meat foam, paint, soapy water, blood, glycerin | 200-400 |

| Generally | Mud, suspended solution, industrial wastewater, paint pigment, waste silk water (sugar), mash, fish, wheat bran, rapeseed oil sediment | 100-300 |

| Serious | Lumper slurry, clay, mud, pottery | 50-150 |

* When the specifications of the pump are large, the speed should be lower.

* The special cases that are delivered and their wear characteristics are given in the table. Please note that the characteristics of the medium change with the change of the concentration and temperature.

Table 3: Select the pump speed according to the medium viscosity

| Medium viscosity (cst) | 1-1000 | 1000-10000 | 10000-100000 | 100000-1000000 |

| Rotating speed (rpm) | 200-400 | 100-300 | <200 | <100 |

* You must also be based on experience when choosing a speed, because some other factors also affect the choice of speed. At the end, it is best to negotiate with the manufacturer while determining the above values.

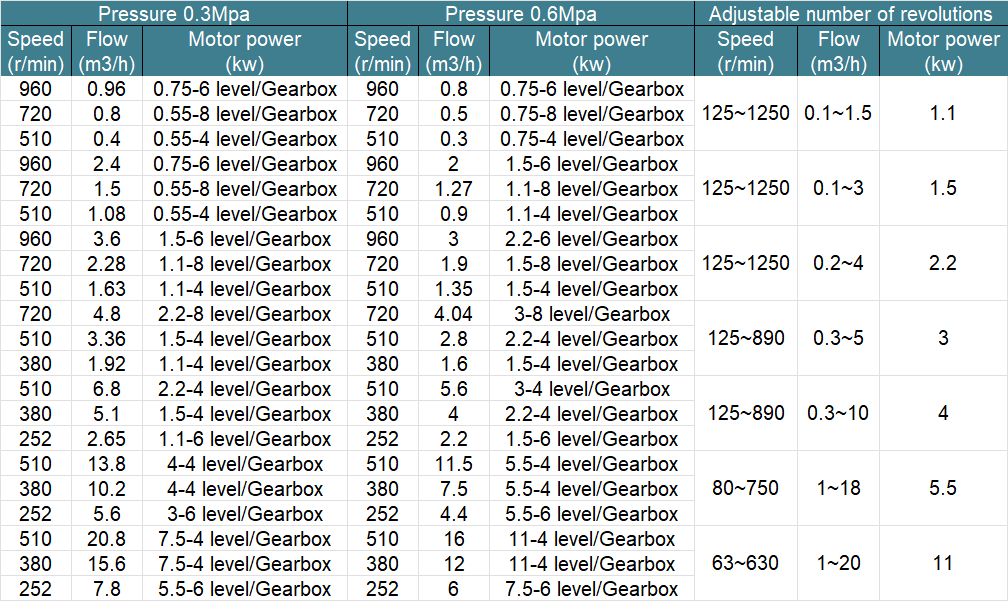

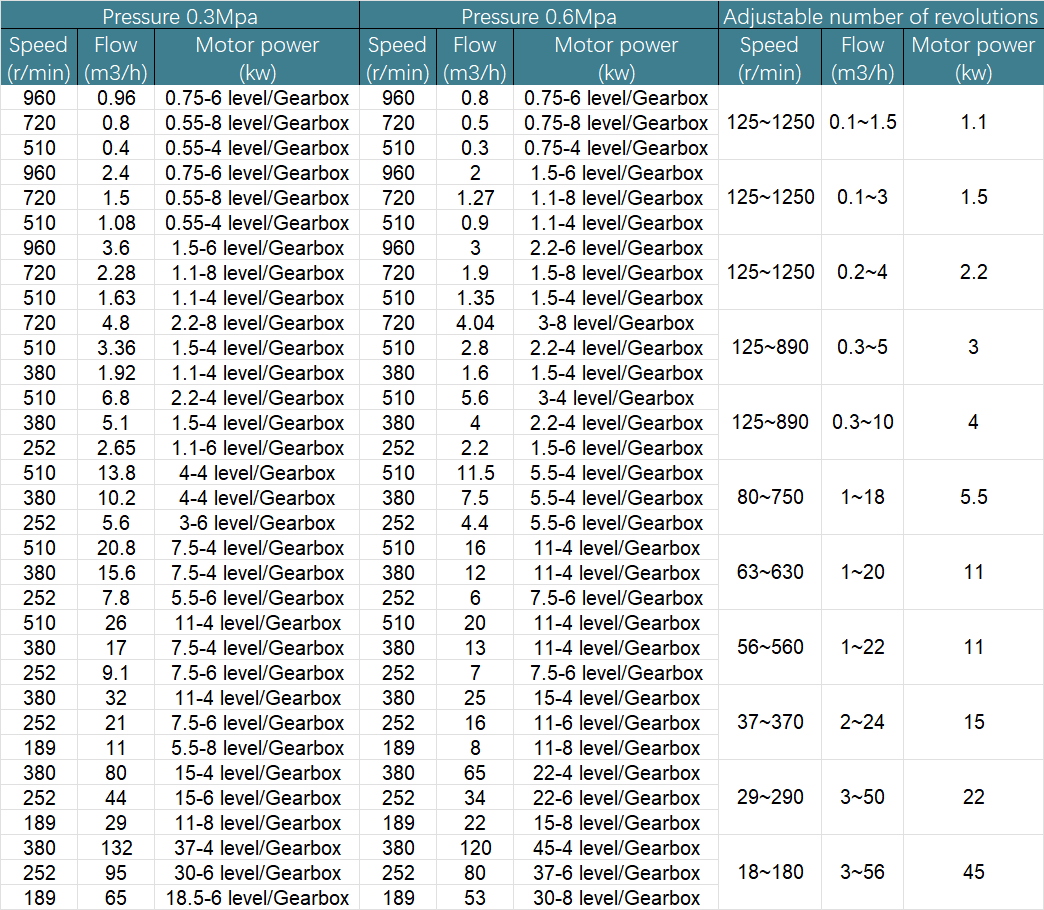

Single-level, performance parameters of gear transmission, electromagnetic speed regulating motor plus gear transmission, or stepless transmission motor with gear:

Performance parameters are used for G -type series, NW series, BN series, C -type series, etc. For specific selections, you can contact engineers

Single -level, performance parameters of gear transmission, electromagnetic speed regulating motor plus gear transmission or stepless transmission motor with gear gear:

Food-Grade Screw Pump FAQ

Q1: What is a food-grade screw pump?

A food-grade screw pump is a type of pump specifically designed for handling food and beverage products. It features a screw-like rotor that rotates within a stator, creating a continuous flow of liquid or semi-liquid substances. The pump is made from materials that comply with food safety regulations and maintain the integrity and hygiene of the pumped products.

Q2: What are the advantages of using a food-grade screw pump?

Using a food-grade screw pump offers several advantages, including:

- Gentle product handling: The pump’s design ensures minimal product shearing, preserving the quality and integrity of the food or beverage being pumped.

- Hygienic operation: Food-grade screw pumps are manufactured from sanitary materials, reducing the risk of contamination and ensuring compliance with food safety standards.

- Efficient performance: The pump’s efficient design enables high volumetric efficiency, resulting in improved productivity and reduced energy consumption.

- Versatility: Food-grade screw pumps can handle a wide range of viscosities, from thin liquids to viscous materials, making them suitable for various food processing applications.

Q3: What types of food and beverage products can be pumped using a food-grade screw pump?

Food-grade screw pumps are suitable for pumping a wide range of products, such as:

- Dairy products: Milk, cream, yogurt, and cheese.

- Sauces and dressings: Tomato sauce, mayonnaise, salad dressings, and condiments.

- Beverage concentrates: Fruit juice concentrates, syrups, and concentrates for soft drinks.

- Soups and purees: Vegetable soups, fruit purees, and baby food.

- Chocolate and confectionery: Liquid chocolate, caramel, and filling creams.

Q4: Are food-grade screw pumps easy to clean and maintain?

Yes, food-grade screw pumps are designed to be easily cleaned and maintained. They are constructed with smooth surfaces, minimal dead spaces, and easy disassembly features to facilitate thorough cleaning. Regular maintenance, such as lubrication and inspection, ensures the pump’s optimal performance and longevity.

Q5: What safety measures should be taken when using a food-grade screw pump?

When using a food-grade screw pump, it is important to follow these safety measures:

- Ensure proper installation and secure connections to prevent leaks or spills.

- Use appropriate personal protective equipment (PPE) when working with the pump or handling the pumped products.

- Adhere to food safety guidelines and regulations to prevent cross-contamination and ensure hygienic operation.

- Regularly inspect the pump for any signs of wear, damage, or contamination and address any issues promptly.

Q6: Can a food-grade screw pump handle high-viscosity products?

Yes, food-grade screw pumps are designed to handle high-viscosity products effectively. The pump’s unique design, with its rotating screw and stator, allows for consistent flow even with thick or viscous substances. This makes them ideal for pumping products such as sauces, pastes, and creams.

Q7: Where can I purchase a food-grade screw pump?

Food-grade screw pumps are available from various suppliers and manufacturers. It is recommended to contact reputable suppliers specializing in food processing equipment. They can provide information on suitable models based on your specific requirements.